Cutting

Home / Cutting / Tool Blanks > PCD/MCD Wire-drawing Die Blanks

PCD/MCD Wire-Drawing Die

Core materials: ND,PCD, MCD,HPHT

Core Shape: Round,Square,Hexagon,Octagon and other customized shapes.

Applications Field: high-precision wires used in electronic devices, radar, television, instrumentation and aerospace

Characteristic: strong wear resistance and extremely high service life

What is wire-drawing die

Wire drawing die usually refers to a mold for drawing variety of metal wire and fiber wire.

All drawing dies have a hole in the center of a certain shape, round, square, octagon or some other special shape. The metal decreases in size and even changes shape as it is pulled through the die holes.

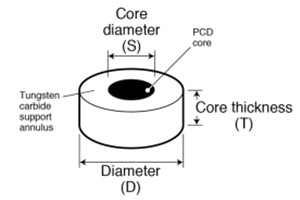

The typical structure is a cylindrical (or slightly tapered) ND/PCD/CVD/MCD die core tightly embedded in a circular steel case, There are Bell radius, Entrance angel, approach angle, bearing and back relief in the inner hole of the die core.

.jpg)

Applications of Wire-drawing Die

Wire drawing dies are widely used in electronic devices, radar, television, instrumentation and aerospace, as well as commonly used tungsten wires, molybdenum wires, stainless steel wires, wire and cable wires and various alloy wires are drawn with diamond wire drawing dies.

Types of wire-drawing die

1. ND wire-drawing die

The natural diamond wire drawing die has strong wear resistance and extremely high service life due to the use of natural diamond as raw material.

2.PCD wire-drawing die

pcd wire-drawing has the advantages of high hardness, good thermal conductivity, strong wear resistance, not easy to break, long service life and high economic benefits. It is suitable for drawing various metal wires.

Advantages of PCD wire-drawing die

-Much long use life

-Suitable for long production runs

-Best choice for highly corrosion wire materials

-Suitable for titanium wire materials

-Wire remains round, even with significant die wear

Specifications of PCD wire drawing die blanks

Cobalt-based polycrystalline diamond wire drawing die blank (round/H hexagonal)

| ADDMA No. | Sizes | grit sizes(μm) | Maximum recommended hole diameter | ||

| ΦD(mm) | Φd(mm) | T(mm) | |||

| D6 | 2.5 | 1 | 3,10 | 0.4 | |

| D6 | 3.2 | 1 | 3,10 | 0.5 | |

| D12 | 3.2 | 1.5 | 3,10 | 1 | |

| D15 | 5.2 | 2.5 | 5,10 | 1.5 | |

| D18 | 5.2 | 3.5 | 5,10 | 2 | |

| D21 | 7.2 | 4 | 5,10 | 3.1 | |

| D24 | 9.5 | 5.3 | 5,10 | 4.4 | |

Polycrystalline diamond wire drawing die blank with carbide support

| ADDMA No. | sizes | Concentricity | grit sizes(μm) | Maximum recommended hole diameter | ||

| D(mm) | d(mm) | T(mm) | ||||

| D12 | 8.12 | 4.2 | 1.5 | 0.25 | 3,5,10,25 | 1 |

| D15 | 8.12 | 4.2 | 2.3 | 0.25 | 3,5,10,25 | 1.8 |

| D18 | 8.12 | 4.2 | 2.9 | 0.35 | 3,5,10,25 | 2.3 |

| D21 | 13.65 | 6.9 | 4 | 0.4 | 3,5,10,25 | 3.5 |

| D24 | 13.65 | 6.9 | 5.3 | 0.5 | 3,5,10,25 | 4.6 |

| D27 | 24.13 | 12..9 | 7.5 | 0.5 | 5,10,25 | 5.4 |

| D27 | 24.13 | 12.9 | 8.7 | 0.5 | 5,10,25 | 5.8 |

| D30 | 24.13 | 12.9 | 12 | 0.5 | 5,10,25 | 7.6 |

| D30 | 24.13 | 15.6 | 12 | 0.5 | 10,25 | 9 |

| D33 | 24.13 | 15.6 | 16 | 0.5 | 10,25 | 10.5 |

| D30 | 30 | 18.3 | 13.5 | 0.6 | 25 | 11.2 |

| D33 | 30 | 18.3 | 15.5 | 0.6 | 25 | 12 |

| D36 | 30 | 18.3 | 18.5 | 0.6 | 25 | 12.7 |

Other specifications can be customized, diamond outer diameter 2.5mm~40mm, thickness 1mm~25mm The maximum recommended aperture is mainly the recommended size for soft wires such as copper wires and aluminum wires. For harder materials, it generally does not exceed 65% of the recommended size.

3.CVD wire-drawing die

Single crystal diamond is a synthetic diamond with high purity, no impurities and high stability. These quality characteristics also make the material have extremely high hardness and stable wear resistance.

CVD wire-drawing die is mainly used for filament and ultra-fine wire drawing, or maintains a wide range of applications in applications requiring excellent wire surface finish and good heat dissipation performance.

Advantages of CVD wire-drawing die

-Good for fine and super fine wires

-Low surface friction

-Smooth wire surface

-Ultra-high accuracy wire available

Moresuperhard provide high grade PCD/CVD/HPHT plates for wire-drawing die

PCD blanks for wire-drawing die

CVD plates for wire-drawing die

HPHT plates for wire-drawing die

Ultrasonic Polishing Machine for Diamond Wire Drawing Dies

Diamond Polishing paste for Diamond Wire Drawing Dies

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088