Grinding

Home / Grinding / PCD Grinding Machine > BDM-902 PCD CBN Tool Grinding Machine

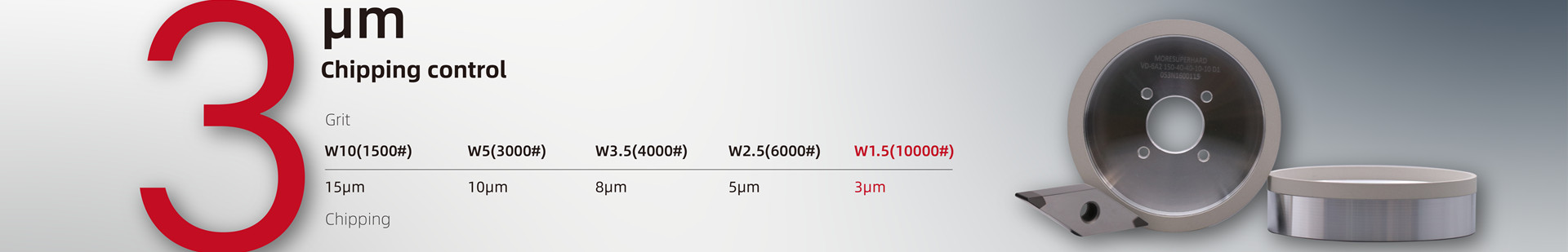

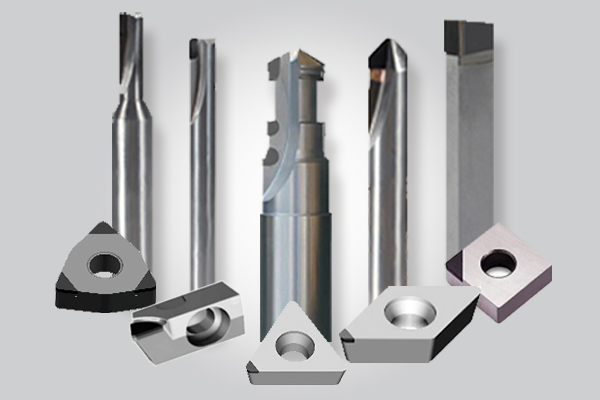

Tool grinding machine for grinding and regrind PCD, CBN, MCD/CVD, ceramic, carbide, HSS tools

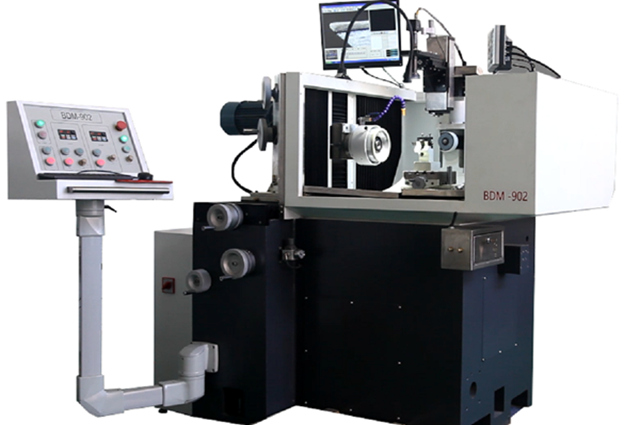

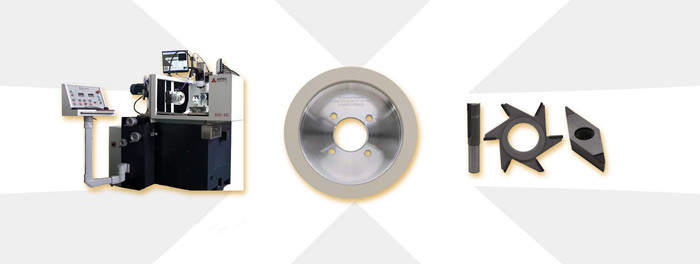

- BDM-902 is a manual high- accuracy, high-efficient universal grinding machine

- Replace Ewag RS15 grinding machine

- Key components are all from famous brand (NSK, SCHNEEBERGER, MOTOVARIO, CAMOZZI, FAGOR etc.)

BDM-902 manual tools grinding machine

BDM-902 is a manual high- accuracy, high-efficient universal grinding machine(which can replace Ewag RS15 grinding machine in an economic way) with many advanced functions such as constant pressure feeding, fast feeding, and withdrawing, online measurement and inspection, online wheel dressing.

Features of BDM-902 tools grinding machine

• Low-vibration, high-strength grey cast iron machine base.

• Pneumatic constant pressure feeding, fast feeding and withdrawing.

• Precise bearing, high strength linear guiding, ball screw.

• High precise mechanical spindle.

• Integrated dressing of the grinding wheels.

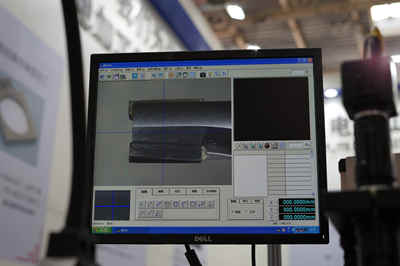

• Integrated on-line inspection and measurement system.

• Integrated the tool position display system.

Key components of BDM-902 are all from famous brand

1. NSK bearing

2. SCHNEEBERGER guiding

3. MOTOVARIO decelerating motor

4. CAMOZZI pneumatic components

5. FAGOR optical scale etc.

* (BDM-902 Equiped with our special fixtures, the machine is not only successfully used in any kinds of tools high-efficient grinding, but also applied in machining high- accuracy milling cutter and reamer with ±3μm dimensional accuracy and Ra0.5 surface roughness) .

Parameter of BDM-902 tools grinding machine

| Grinding spindle travel | 430mm |

| Grinding spindle height adjustment | 120mm |

| Grinding spindle inclination | -5-25 |

| Grinding spindle oscillation size | 0-50mm |

| Grinding spindle oscillation frequency | 0-45 strokes/min |

| Grinding spindle speed | 1000-4500rpm |

| Grinding spindle motor power | 2.2kW |

| Slider feeding size | 120mm |

| Worktable swiveling angle | 0-240 |

| Worktable travel | 60×60mm |

| Contact pressure | 0-400N |

| Image magnification | 10-65x |

| Optical tube travel (WUV) | 50×150×150mm |

| Object distance of optical tube | 300mm |

| Optical scale resolution | 0.001mm |

| Encoder resolution | 0.018° |

| Total power | 4kW |

| Dimension | 1780X1850X1450mm |

| Net weight | about 2800kg |

Standard configuration of BDM-902 tools grinding machine

| Main part of machine |

| power supply and control system |

| Coolant system |

| On-line inspection system |

| Positioning display system |

| Machine light and LED ring light |

| Quick clamping fixture |

| Pivot electric locking device |

| Standard accessories |

Application of BDM-902 grinding machine

Grinding and regrinding PCD, CBN, MCD and CVD tools, ceramics, carbide, HSS tools.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088