Having been in the machining industry for many years, you must be no stranger to tool failure.

Flank wear

Flank wear refers to the abrasion loss of the flank of the tool immediately below the cutting edge. The carbide particles in the workpiece material or the work-hardened material rubs against the blade. Small pieces of the coating peel off and the blade rubs. The cobalt element in the blade is finally separated from the crystal lattice, reducing the adhesion of the cemented carbide and thus peeling off.

Crumble

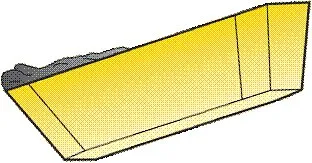

Flank chipping

Rake area edge

Certain workpiece materials may create a rake area between the chip and the cutting edge. When the continuous lamination of the workpiece material is connected to the cutting edge, built-up edge will occur. The built-up tumor is a dynamic structure. During the cutting process, the cut surface of the built-up edge continuously peeled off and reattached.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088