Customer's requirements

Regrinding used MCD cutting tools chipping control under 3μm.

Application of MCD cutting tools

Processed Cellulose Acetate Eyeglass Frames

What is Cellulose Acetate?

Cellulose acetate refers to a thermoplastic resin obtained by esterification using acetic acid as a solvent and acetic anhydride as an acetylating agent under the action of a catalyst. It is the earliest cellulose derivative to be commercially produced and continues to develop. Organic acid esters. As a porous membrane material, cellulose acetate has the characteristics of high selectivity, large water permeability, and simple processing.Until 1940, cellulose acetate became one of the most critical raw materials in the production of eyeglass frames.

Why are acetate eyeglass frames so unique?

Acetate frames can be produced in a variety of colors and patterns without the need to paint the frames. The layering of acetate brings varying degrees of transparency and pattern to the frames. This beautiful design then makes acetate frames a more ideal choice than regular plastic eyeglass frames

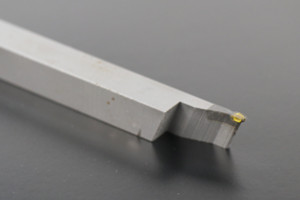

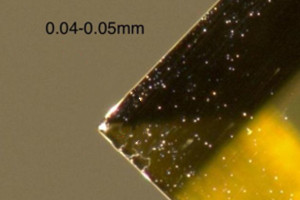

Step 1 Detect MCD tool wear under a microscope to determine the MCD tool chipping

According to the test results under the Keyence microscope, the chipping of the tool is 40-50μm.

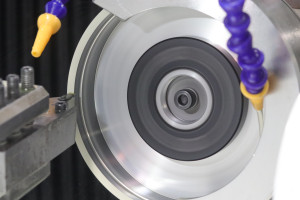

Step 2 According to the chipping condition of the tool, select a ceramic diamond grinding wheel with appropriate grit size for rough regrinding the MCD tool.

According to the chipping 40-50μm,Moresuperhard technician choose W5 vitrified diamond grinding wheel for rough regrinding MCD cutting tools.Using M50 CNCgrinding machine for rough grinding ,after rough grinding ,the chipping of mcd tools is 7μm.

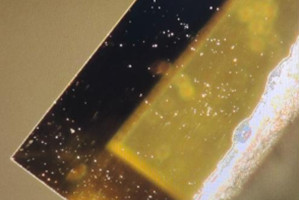

Step 3 Finishing Regrinding MCD tools

Choosing Moresuperhard 10000# vitrified diamond grinding wheel for finishing grinding MCD tools,after finish regrinding,the chipping of mcd cutting tools is 1.5μm.

After grinding experiments, Moresuperhard provides customers with mature MCD tool grinding solutions.Using vitrified diamond grinding wheel for regrinding MCD cutting tools.Grit sizes choosing W5,W1.5 for rough grinding and finish grinding.The customer later needto grind the single crystal cutting tools by himself, so he purchased Moresuperhard's ceramic diamond grinding wheel specifically for grinding single crystals diamond tools.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088