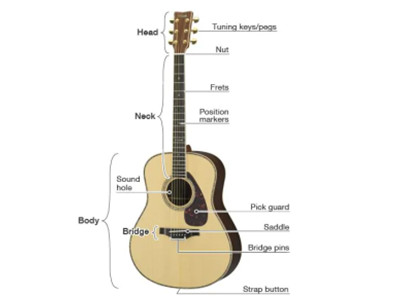

Components of a guitar

Generally, a guitar consists of three parts: the headstock, the neck, and the soundboard, each of which is composed of different structures. The headstock includes the pegs and the nut. The neck includes the frets (pins), the fingerboard, and the fret marks. When the soundboard vibrates, the air inside the body of the guitar also vibrates and amplifies the sound of the strings.

The headstock

Includes the pegs and the nut. The pegs are used to adjust the pitch of the strings; the nut is used to support the strings. In addition, the brand of the guitar is generally marked on the headstock.

The neck

Includes the frets (pins), the fingerboard, and the fret marks. The frets (pins) are important parts that determine the pitch. Folk guitars generally have 20 (or 21) frets; the fingerboard is the position between the frets, which is the position pressed by the left hand when playing. Each string has a corresponding fretboard, which produces different pitches; the fret marks can be used as "position marks" or "overtone marks", which can help us find the position quickly.

The Soundboard

Perhaps the single most important element influencing the sound of a guitar is the soundboard. When the strings are plucked, the vibrations are transmitted to the top through the bridge. When the top vibrates, the air inside the guitar body also vibrates and amplifies the sound of the strings.

Introduction to guitar frets

There is a nut on the fingerboard of the guitar neck and is equipped with many narrow and slightly raised metal horizontal grids, called "frets", also called frets, which divide the strings into many semitones.

The performance of your guitar depends largely on the condition of its frets. Every time you press down on a string, the friction between the metal and the frets quietly wears away at the frets. Over time, fret wear can cause clicks and intonation problems.

Guitar Fret material

1.Frets made of "nickel silver" do not contain silver. The typical composition is 18% nickel, 80% copper, and a small amount of other metals such as zinc, lead, or cadmium. High-quality frets have a higher zinc content and a lower copper content. Jescar is one of my favorite fret brands. The fret composition of their frets is 62% copper, 18% nickel, and 20% zinc. Relatively speaking, the texture is harder than ordinary frets, so it is more durable.

2.Another option is stainless steel frets. But stainless steel is too hard and very difficult to handle. It will greatly increase the time for repair and replacement, and cause more wear and tear on repair tools. But stainless steel frets are indeed much more durable than traditional frets, and the price is relatively expensive. So, if you don't plan to replace or polish the frets for a long time, stainless steel is a good choice.

How to Repair Guitar Frets?

The two biggest problems with fret wear are dents and flats.The fret finishing process is complicated, requiring grinding the arc block (leveling the bumpy frets), then correcting the crown (making the crown regain the perfect arc), then polishing, chamfering, etc.

1. Check the frets First, carefully check all the frets for worn or damaged ones. Look for dents, deformations, or excessive wear on the frets.

2. Clean the fretboard Clean the fretboard using distilled water or lemon oil and a polishing cloth. This helps remove dirt and grease and ensures a clean work area.

3. Protect the fretboard with masking tape Apply masking tape on both sides of each fret to protect the fretboard from files and polishing tools.

4. Refine the frets Minor wear: If the frets have minor dents or wear, you can use a fine sandpaper or fret file to gently smooth them out. Moderate wear: For moderate wear, you may need to smooth the tops of the frets with a fret file or a grinding block, then check the fret height with a probe to make sure they are even. Severe wear or damage: For severely worn or damaged frets, you may need to replace the frets. Carefully remove the old frets with fret pliers, then tap the new frets into place with a fret hammer.

5. Flatten the frets Use a fret flattening tool, such as a fret leveler, to make sure all frets are at the same height. If any frets are sticking out, use a file or a grinding block to trim them.

6. Polish the frets Use a fret polishing tool or a polishing cloth to polish each fret to smooth it out and restore its shine.

7. Remove the masking tape and clean it Remove the masking tape and clean the fretboard again with a polishing cloth and lemon oil or distilled water.

8. Tune the guitar Once you have finished repairing the frets, tune the strings and check the intonation and feel of the guitar. Make sure there are no buzzing or resonance issues.

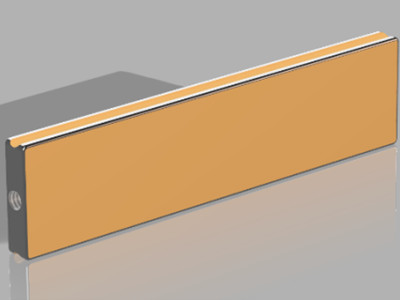

Moresuperhard provide specific diamond tools help you repair your guitar frets more quickly.Electroplated diamond grinding tools help you trim the fret surface to remove wear and uneven parts.Diamond fret files have high hardness,good wear resistance and long services life.Diamond frets files have high grinding efficiency and trimming precision for guitar frets.

Diamond fret files can easily process hard metals and high-hardness frets with their ultra-high hardness and excellent cutting performance, significantly improving work efficiency. Their excellent wear resistance and low heat generation characteristics ensure that the files remain sharp and the shape of the workpieces remains stable during long-term use. At the same time, the surface of diamond files is not easy to clog, and they are easy to clean and maintain. They are suitable for finishing work that requires high precision and high finish, such as flattening, crowning and polishing of guitar frets. A variety of shapes and specifications make them widely applicable and have unparalleled advantages in various professional and industrial applications.

How to use this diamond tool:

Upper and lower planes---grind the ends and corners of the frets

Grooves on both sides: polish/repair the fret crowns.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088