Diamond Jewelry Processing :Design → scribing → sawing → edging → polishing

1.Diamond rough design

Diamond rough design is the first step in diamond cutting. The traditional method is to use a magnifying glass to observe the shape, texture and internal flaws of the diamond rough to analyze the approximate finished weight of the rough diamond. The person doing this work must have extensive experience and be proficient in processing technology. The ultimate goal is to create the largest, cleanest, and most perfect diamond to reflect the value of the diamond as high as possible. At present, most diamond processing plants have improved to use computer analysis instruments (SARINE) to preliminarily design rough diamonds.

2.Scribing

There are two points that need to be paid attention to when scribing. One is to try to maintain the weight of the diamond, and the other is to try to reduce the diamond inclusions through the next step of cutting. Therefore, the position of the scribing is particularly important. The scribe uses a magnifying glass to study the structure of the rough diamond. This work may take several months for large diamonds and a few minutes for ordinary rough diamonds. After observation, experienced staff use special ink to mark the rough diamond, indicating that the rough diamond should be divided along this line. If it is a traditional cutting method, the lines must be drawn along the natural grain direction of the diamond.

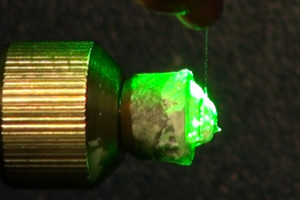

3.Sawing Rough Diamond

Most rough diamonds are cut by sawing. Diamond is the hardest substance in the world. Only diamonds can cut diamonds. Therefore, a raw metal piece is coated with diamond powder and lubricant. Fix the diamond on the upper clip and rotate the metal piece at high speed to saw the diamond. Nowadays, laser cutting technology is mostly used for rough diamond cutting.

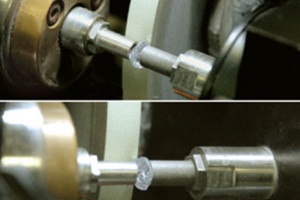

4.Edging

The sawed diamonds are sent to the rounding department for rounding and shaping. In this step, the diamond can be shaped into round, heart-shaped, oval, cusp-shaped and other shapes according to the design requirements. Generally, TSP diamond or diamond grinding wheels are used for grinding.

How to choose diamond bruting wheel when edging diamond?

Diamond grinding wheels are widely used in diamond processing, which is where the name comes from. It is suitable for polishing natural diamonds and can replace polycrystalline diamond (PDC). It has the common characteristics of diamond and ceramic bonding agents. Compared with ordinary corundum and silicon carbide grinding tools, it has stronger grinding force, lower temperature during grinding, and smaller grinding tool wear; it can adapt to the effects of various coolants; The shape retention of the grinding tool is good during grinding, and the workpiece can be ground with high precision.

Common specifications of diamond bruting wheels:

170*10*32*14 325/400;

170*10*32*14 W40;

170*10*32*14 W20

Grain size selection: 325/400 roughing; W40 semi-fine grinding; W20 fine grinding.The grinding wheel for diamond backing and the grinding wheel for diamond surface are rough machining. It is recommended to use 325/400 grit. For the grinding of diamond edge wheel, you can choose W40 grit. It has high grinding efficiency and moderate polishing. If it is used for diamond polishing It is recommended to use W20 precision grinding wheel.

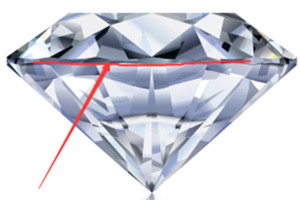

5.polishing

The polishing process is to grind out all the facets (facets) on a cast iron disc coated with diamond powder and lubricating oil, so that the diamond emits an attractive brilliance. The grinding process usually involves first making 8 large faces on the bottom layer, and then making 16 facets. Adding the culet, there are a total of 25 facets, and extending from this are the triangular facets, the kite face and the girdle facets, a total of 33 facets. In this way, a round diamond has a total of 58 facets. If there is no culet, There are 57 small facets in total.

<< :Summary of the 7th Carbon Materials Conference

<< :Grinding Case -How to Grind PCD and Iron Composite Workpieces

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088