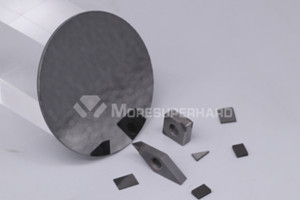

The characteristics of PCD material

The diamond crystals in the PCD diamond layer are disorderly arranged, isotropic, and have no cleavage planes. They have the high hardness, high wear resistance and high thermal conductivity of diamond; the cemented carbide layer as the base has high impact toughness and Weldability. Therefore, PCD is particularly suitable for cutting tools of non-ferrous metals and non-metallic materials and supporting wear-resistant parts of various instruments and equipment.

The characteristics of iron material

In industry, iron is divided into two types: pig iron and wrought iron - pig iron contains 1.7-4.5% carbon, and wrought iron contains less than 0.1% carbon. Characteristics: Excellent fluidity, low cost, good wear resistance, low solidification shrinkage, very brittle, high compressive strength, good machinability. Purpose: Iron has been used for hundreds of years in construction, bridges, engineering components, homes, and kitchen appliances.

We all know how to choose a grinding wheel for grinding a single material workpiece.Usually,we choose vitrified diamond grinding wheel for grinding PCD material workpiece like PCD cutting tools and we choose cbn grinding wheel for grinding iron material.We do not choose diamond grinding wheel for grinding iron,Above 800 degrees Celsius, diamond reacts with iron to form stable Fe3C. When using a diamond grinding wheel to grind iron materials, friction generates high temperatures, causing "nodulation" to occur on the surface of the grinding wheel.

Customer's workpieces

As we can see,this workpiece have three materials need to be processed.The black part in the middle is PCD, the two slender strips are carbide, and the remaining area is made of iron.

Grindingrequirements

Grind the surface of the workpiece smooth so that the PCD will not crack or scratch.

Moresuperhard developed and manufactured 1A1 D350 vitrified diamond grinding wheel for grinding PCD+iron workpieces.

Basis for formulating grinding plan

The hardness of PCD is much higher than iron and cbn grinding wheel can be not used for grinding PCD material.Commonly we do not recommand diamond grinding wheel for grinding iron material,but if the grinding wheel speed is not high and coolant is used when grinding,diamond grinding wheel also can be used for grinding iron material.

After the test ,More superhard help the customer solve their grinding problems successfully.Commants from our customer:The surface quality is fine.The services life of diamond grinding wheel is long.The dressing solution is also good.

Moresuperhard is always focus on helping you solve your grinding difficults.We provide diamond grinding wheel ,grinding machine and dressing tools for you.Please contact us freeely.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088