Induction

Very glad to receive good feedback from our customer.Customer is a diamond stylus manufacturer from Russia.Due to the difficult situation in the Russia, he decided to make diamond styluses himself. A lot of money was spent, hundreds of experiments were made. He ended up building a brand new diamond polishing machine.He used vitrified diamond grinding wheel for grinding diamond stylus before,but the grinding results was not ideal. Then,Moresuperhard provide metal diamond grinding wheel suit the grinding machine for polishing cvd diamond stylus.

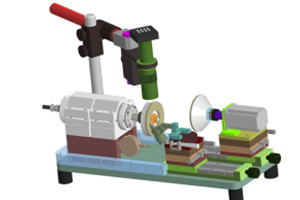

Metal diamond grinding wheel for grinding diamond stylus with manual grinding machine

Testing results from customer:

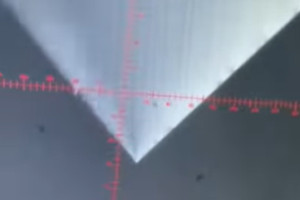

Workpieces:CVD diamond stylus

specifications of diamond grinding wheel:1A2 100*20*25*25*10 10000#

Grinding wheel speed:9000rpm

Sharpening time:1minute

Recomand for metal diamond grinding wheel from our customer

"I have two diamond wheels bought from Moresuperhard company. I have 2-3 micron grit and they work great. You can find them in one of my publications. You can say 0.25 or 0.5, they will also work well"

Congratulations to the customer for the successful experiment

We are very happy that our metal diamond grinding wheel help our customers achieve their grinding golas.We are willing to make experiment with our customers,moresuperhard provide customized diamond grinding wheel for our customer ,even our customer still need one piece of grinding wheel for test.

Why metal diamond grinding wheel is suitable for grinding cvd diamond?

1.very high grinding efficient and grinding precision

2.long services life,two times grinding life time than vitrified diamond grinding wheel

3.Good shape retention, good wear resistance and good thermal conductivity

Friendly reminder:Metal diamond grinding wheels require specialized electrical machining and dressing equipment for xiu'zheng

<< :How to polish large size single crystal diamond?

<< :Grinding Case-1A1 Diamond grinding wheel for Round PCD Cutting Tools

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088