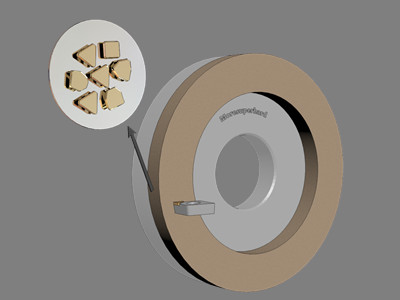

Diamond wheel for grinding SCD, MCD, CVD cutting tools

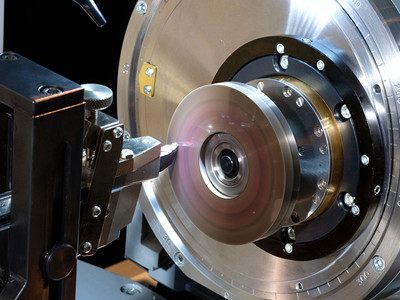

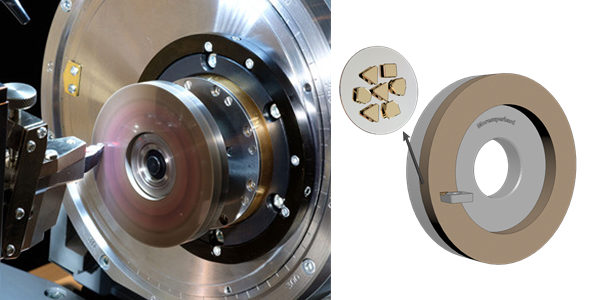

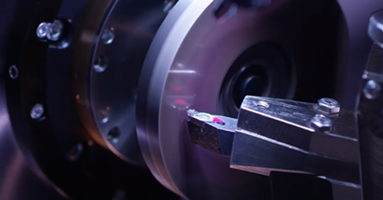

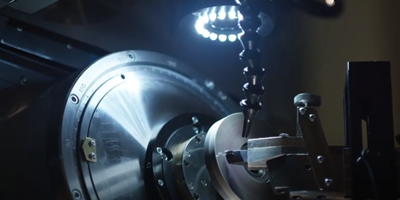

Grinder: Coborn PG series grinding machine

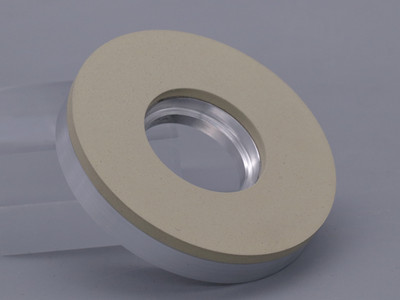

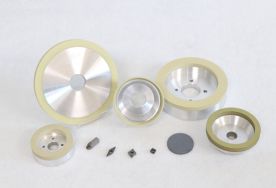

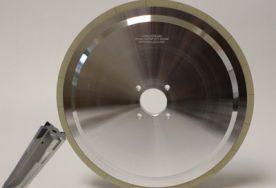

1A2 diamond wheel for finish grinding single crystal diamond

Bonded: vitrified bond and metal bond

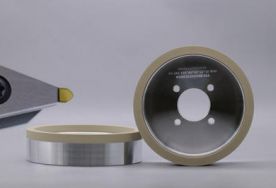

Moresuperhard diamond wheel for precision grinding single crystal diamond, With Ultra-high precision. The PG seris is a CNC grinding machine for single or mono crystal diamond tool manufacture. The PG seris enables the automated production of ultra-high precision diamond tools.

Coborn PG series offers automated, ultra-high precision grinding, designed to meet the most complex of demands by toolmakers working with natural (MCD) or synthetic single crystal diamond (SCD), manufactured by either high pressure high temperature (HPHT) or chemical vapour deposition (CVD).

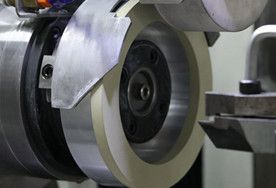

The applications of diamond grinding wheels

Diamond grinding wheels are used for grinding PCD cutting tools, PCBN cutting tools, CVD tools, MCD tools, milling cutter, reamer, drill and regrinding etc. It can be used for making facetted and convex radius tools using: natural diamond, HPHT, synthetic diamond, CVD synthetic diamond.

MCD tools are used for milling carbon steel, die steel, alloy steel, stainless steel, heat-resistant steel, gray cast iron, ductile iron, malleable iron, etc.

The specifications of diamond wheel for grinding single crystal diamond

| Model | D(mm) | T (mm) | H (mm) | W (mm) | X (mm) |

| 1A2 | 86 | 12 | 30.16 | 25 | 5.5 |

| 75 | 16 | 30.16 | 15 | 7.5 | |

| 85 | 12 | 30.16 | 20 | 5.5 | |

| Grit: 325/400, W10 (1500#), W5 (3000#), W3 (5000#) 2000# 3000# 10000# 15000# 20000# | |||||

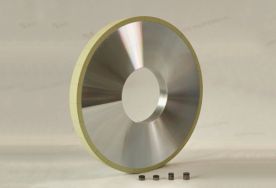

Vitrified Bond Diamond Grinding Wheel

Precision grinding for natural diamond (MCD) or synthetic single crystal diamond (SCD) cutting tools.

Metal Bond Diamond Grinding wheel

Natural (MCD) or synthetic single crystal diamond (SCD), manufactured by either high pressure high temperature (HPHT) or chemical vapour deposition (CVD). Metal bond diamond wheel can used for single crystal diamond tool manufacture with ultra-high precision.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088