Overview of PCD Micro Drilling Tools

Features of PCD drills

PCD micro-drills have high hardness, are wear-resistant, and have a relatively longer service life than traditional alloy micro-drills;

PCD micro drill products are widely used and can process non-ferrous metals and inorganic non-metallic materials with high processing accuracy;

PCD micro drills produce better hole wall quality than traditional alloy micro drills.

Applications of PCD drills: semiconductors; national defense; aerospace; chips, communication electronics; automotive electronics; high-end medical equipment;

Introduction to zirconia ceramics

Zirconia ceramic is a high-hardness precision ceramic material with a hardness of over HV1250.

Features: Excellent thermal insulation; good wear resistance; good surface finish; high fracture toughness;

Application: Pump parts; molds; cutting tools; cutting blades; communication hardware...

Difficulties in precision ceramic hole processing

It is required that the material has no obvious cracks after drilling;

The hole wall has high requirements for smoothness, no burrs and no chipping;

High dimensional accuracy requirements, the minimum hole diameter is only 0.1mm

Traditional Micro drill grinding manufacturing technology

Precision grinding wheel grinding is the basis for the manufacturing of all metal cutting tools. Traditional grinding technology requires special precision grinding wheels to be specially customized for different drill geometric angles and processing characteristics. Therefore, the equipment configuration is relatively complex and the precision tool grinder is expensive. Micro drills are formed and manufactured by precision grinding, which must use special tool precision grinders supplemented by precision measurement systems and ultra-fine-grained grinding wheels.

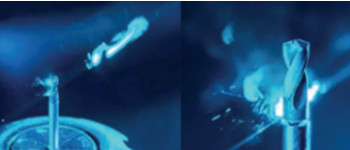

PCD Micro drill grinding manufacturing technology

For PCD material tool manufacturing, laser processing has great technical advantages. Due to the existence of diamond hard phase and cobalt metal bonding phase in PCD, during the traditional processing process, the diamond grinding wheel or wire cutting wire cannot completely cut through the diamond particles in PCD, and the particles are mainly removed by falling off and shattering as a whole. , so the quality of the PCD cutting edge is poor, with obvious jagged defects, and a smaller particle size grinding wheel or abrasive paste is required for grinding and polishing. In high-frequency laser processing, both the hard phase and the bonding phase are removed by material sublimation. The removal process is coordinated and excellent edge processing quality can be obtained.

Defects of laser processing PCD micro-drilling tools

The main disadvantage of laser processing is the thermal impact on the tool surface layer, further grinding and polishing is required to improve processing quality.

Moresuperhard as diamond grinding wheel manufacturer,We have been working hard on the precision grinding of PCD micro drill tools.As we all know,vitrified diamond grinding wheel is suitable for grinding PCD materials for high efficient and precision.In order to solve the problem of thermal damage layer on the surface of PCD micro-drilling tools after laser processing, Moresuperhard developed ceramic diamond grinding wheels for fine grinding of PCD micro-drilling tools.

11V9 vitrifed diamond grinding wheel for grinding PCD drill

If you need more details,please contact us freely.

<< :Causes of burns on the workpiece during grinding

<< :Application of ceramic diamond grinding wheels in the abrasives industry

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088