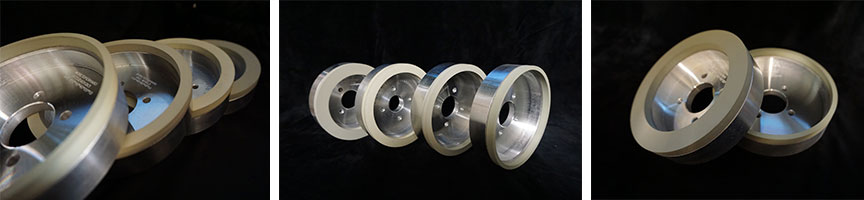

Introduction of vitrified bond diamond grinding wheel

Vitrified bond diamond grinding wheels possess pretty high abrasive resistance, especially in polishing hard and brittle workpiece. It has many advantages like high grinding efficiency, high grinding precision, excellent workpiece's surface grinding, etc

Application of vitrified diamond wheel

Especially for PCD tools rough, semi-fine and fine grinding.

Specification of 6a2 diamond wheel

|

TYPE |

Diameter D (mm)

|

Thickness T (mm)

|

Hole H (mm)

|

Diamond Width W (mm)

|

Diamond Thickness X (mm)

|

|

6A2 |

100 |

40 |

20,32,40 |

5, 10, 15, 20 |

10 |

|

6A2 |

125 |

40 |

32,40 |

5, 10, 15, 20 |

10 |

|

6A2 |

150 |

40 |

32,40 |

2, 3, 5, 10, 15 |

10 |

|

Grit Size: 80# -- 8000# (D213 – D1) |

|||||

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088