Description:

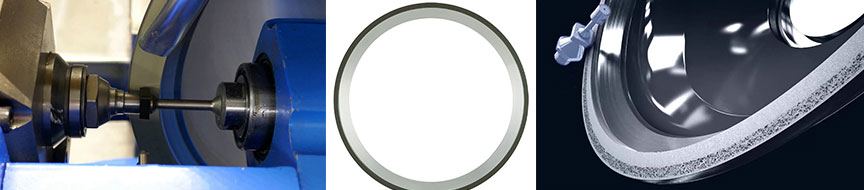

Diamond Wheels for Peripheral Grinding of inserts, must be of a high level of geometrical accuracy, with ability of significant material removal.

We are able to produce various types wheels to suit all popular machines, such as WENDT, WAIDA, AGATHON, EWAG, COBORN, etc.

Features:

Goodsurface accuracy retention

High stock removal efficiency

High durability, long life time

Good edge quality of inserts

Long life

Competitive price

Application:

Mainly used for precise edge grinding of indexable inserts, tungsten carbide inserts, ceramic inserts, CBN inserts.

Applicable machines:

AGATHON:

400 Series: 400 PENTA, 400COMBI, 400SEMI, 400PERI.

350 Series: 350T&B, 350COMBI

250 Series: PA250

WENDT:

400 Series: WAC715, WAC735

350 Series: WAM336

WAIDA:

AP460E

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088