Super-hard cutting tools mainly refer to cutting tools made of diamond or cubic boron nitride. At present, more materials are used: single crystal diamond, PCD polycrystalline diamond, integral CBN, PCBN composite sheet.

Vacuum welding of super-hard tools refers to the completion of the brazing action between the super-hard tool base and the cutter head by heating in a vacuum state. Like flame brazing and high-frequency induction brazing, the ultimate goal of vacuum welding is to make the molten solder flow evenly to all parts of the weld under the action of the capillary pipette to achieve the best welding effect. Therefore, for the super-hard tool products suitable for vacuum welding, selecting suitable solder, proper pre-welding treatment, and correct welding process can make full use of the advantages of vacuum welding and ensure the performance of super-hard tool products.

Vacuum welding needs to place the superhard tools in a vacuum environment for heating, and the entire furnace will reach the welding temperature. Therefore, the size of the tools that need vacuum welding cannot be too large and must be able to be put into the furnace. At the same time, the tool body and blade must withstand temperature changes during the welding process without changing their performance. Tool manufacturers are pursuing high production efficiency. It can be seen that the vacuum welding process is particularly suitable for mass-produced superhard tools with small dimensions and can be heated as a whole. It is not suitable for superhard tools with larger sizes or only local heating. Welding processing of products.

Common superhard tool materials are: ① single crystal diamond; ② PCD polycrystalline diamond; ③ overall CBN; ④ PCBN composite sheet. They have their own requirements for the selection of solder:

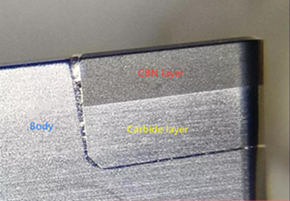

(1) ②④All contain a layer of hard alloy backing, which can be welded with conventional solder (that is, silver welding and brazing are widely used at present);

(2) ①③It is a non-metallic material and requires active solder to weld it to the cutter body (generally metal-based solder can only connect metal to metal, while active solder can not only perform metal-to-metal welding, but also realize metal-to-metal welding). Welding processing of non-metallic materials);

(3) ①②All have the characteristics of diamond, and graphitization will occur at high temperatures, so the vacuum welding temperature needs to be controlled at about 700℃.

(4) The CBN tool produced by ③④ has a very high tip temperature when processing hardened steel. In order to prevent the welding surface from loosening, high temperature solder is required.

In view of the characteristics of superhard tool materials, for vacuum welding, at least two solders must be selected to meet all requirements, namely, a low-temperature active solder for the welding of single crystal diamond and PCD tools; Another high-temperature active solder is used for the welding of integral CBN and PCBN tools. Although the first low-temperature active solder can weld all super-hard tools, it is recommended to use high-temperature solder for CBN tools, so that the stability of CBN tool products at high temperatures will be greatly increased.

Preparation before welding (before entering the furnace)

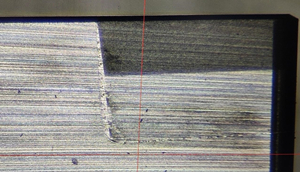

The strength of brazing is determined by many factors. In order to obtain a good brazing seam, it is necessary to control some details that may affect the welding quality. Compared with conventional welding, vacuum welding has stricter requirements for preparation work.

Only when every detail is guaranteed can the best welding effect be obtained. The lack of a certain item or the lack of guarantee will greatly reduce the stability of the welding.

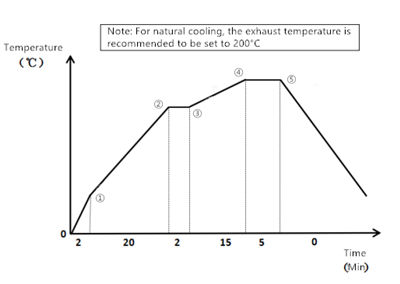

Once the preparations are completed, the tool products are put into the vacuum furnace, and the subsequent production is completely controlled by the heating process. The setting of the vacuum welding heating process curve is mainly restricted by the furnace size, temperature field distribution, the solidus and liquidus of the selected solder, the amount of furnace installed, the size of the weld, etc.

The vacuum welding process can effectively eliminate the influence of air on the superhard tool, and the tool has a good appearance.The heating temperature in the furnace is uniform, the product deformation is small, and the tool is not easy to crack. When the process is stable, the products of each furnace have the same quality, which is especially suitable for the mass production of small-sized super-hard tools.

e mass production of small-sized super-hard tools.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088