Why do vitrified diamond grinding wheels have pores after they are made? Questions from moresuperhard's customers. The customer also asked: Will these pores make the grinding cutting tools chipping? In response to these questions raised by customers, we have summarized the following content to explain the problem.

Why do vitrified diamond grinding wheels have pores after they are made?

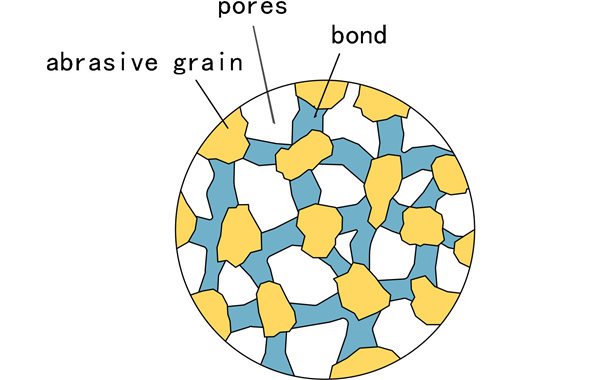

At present, there is no similar problem with the ceramic diamond grinding wheel that moresuperhard supplies to customers. There are two forms of pores in the grinding wheel. One is in the bond, which does not affect the formation of bond bridges between the abrasive particles, the other is between the abrasive particles, which will seriously weaken the strength of the bond bridge and cause the abrasive particles to fall off easily during the grinding process. .

1. The pores of the ceramic grinding wheel are generally caused by the pore-forming agent of the grinding wheel and the wetting agent (which will bubble) in the auxiliary materials, and the gas does not escape and combine. Pore formers are additives that create a pore structure in a material. Additives that increase the pore structure in the material are generally substances that are easily decomposed into gases. For example, adding ammonium bicarbonate to the material and heating it will release carbon dioxide and ammonia gas, which can escape from the material and create a pore structure. The reported pore-forming materials mainly include: naphthalene, sawdust, walnut shell powder, carbon particles, sugar granules, PS microspheres (polystyrene microspheres), PMMA microspheres (polymethyl methacrylate microspheres), plastic particles, inorganic ammonium salts, graphene, etc. Their pore-making mechanisms are different, and the pore-forming effects are also different.

2. The air hole in the grinding wheel, as one of the three elements of the grinding wheel (abrasive, binder and air hole), plays a vital role in chip removal, heat dissipation and cooling during the working process of the grinding wheel.

3. Resin grinding wheels and metal grinding wheels are dense structures with few or no pores. Ceramic grinding wheels have naturally occurring pores. Because of its unique open pore structure, ceramic grinding wheels are better in self-sharpening, dressability, and grinding efficiency, while resin grinding wheels and metal grinding wheels have problems such as grinding heat and self-sharpening due to less or no pores. Become a factor that affects the performance of the grinding wheel. It can be said that it is the natural gas pore structure of the vitrified bond that gives it many unique properties. However, due to the variety of grinding application environments, it is difficult to meet all the needs of grinding only by its own voids. The selection and application of pore-forming agents are also quite important. of. The pores naturally formed by ceramic grinding wheel sintering generally do not exceed 0.02mm.

Therefore, when making vitrified grinding wheels, especially fine-grained grinding wheels, the added auxiliary materials must be mixed evenly and fully fused with diamond under the action of the binder. At present, Moresuperhard uses a pore-forming agent of 400 yuan/kg, which is on the market. Most of them are pore-forming agents of tens of yuan/kg, and the resulting grinding wheel will directly affect the quality of customers' products.

Advantages of Vitrified diamond grinding wheel

* Porous structure vitrified diamond wheel can prevent vertical streaks on workpiece and improve surface quality. Efficient heat removal with open structures that carry coolants into the work zone resulting in less thermal damage to metals.

* Lower grinding costs by allowing to produce more superior edges in less time

* Compare to resin bond and metal bond, our vitrified diamond wheels have high grinding efficiency, good self sharpening and high wear resistance and easy dressing etc

* Vitrified bond wheels offer tool life greater than 150 times that of a resin bond wheel and can be easily trued and dressed on the machine

* PCD tools can reach high efficiency , good surface finish and edge no chipping

The vitrified diamond grinding wheels for sharpening PCD inserts the grain sizes are used: rough grinding D20, finish grinding D15 and super finish grinding D6, D3,D1. In order to obtain good PCD cutting edge quality, the most ideal processing method is still using vitrified diamond wheel to grind pcd . Moresuperhard vitrified grinding wheel to grind R0.01mm PCD inserts. More information about vitrified diamond wheel and grinding wheel pores, please contact us.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088