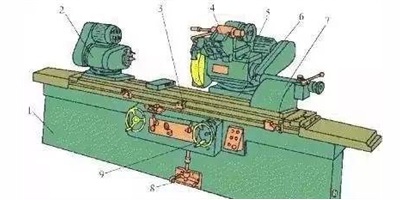

The following figure is the outline drawing of M1432A universal cylindrical grinder. The meaning of the M1432A number is: M—grinding machine class; 1—external cylindrical grinding machine group; 4—general code of universal cylindrical grinding machine; 32—1 / 10 of the maximum grinding diameter, the maximum grinding diameter of the machine is 320mm; A major improvement in performance and structure.

1. The main parts of the grinding machine

-The lathe bed 1 is the basic support of the grinder. It is equipped with a grinding wheel frame 5, a working table 3, a head frame 2, a tailstock 7, and a transverse saddle, etc., so that these components maintain accurate relative positions during work. The inside of the bed is used as an oil sump for hydraulic oil.

-Tailstock The tailstock 7 and the top of the headstock 2 support the workpiece together.

2.Purpose of machine tool

<< :Grinding process of single abrasive grain

<< :Three methods for diamond polycrystalline and synthetic diamond polycrystalline

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088