Grinding

Home / Grinding / PCD Grinding Machine > M50 Manual PCD Tool Grinder

M50 Manual Tool Grinder for grinding and regrinding pcd, cbn, ceramics, carbide and HSS tools

- Economical type PCD Grinder, Cost-effective

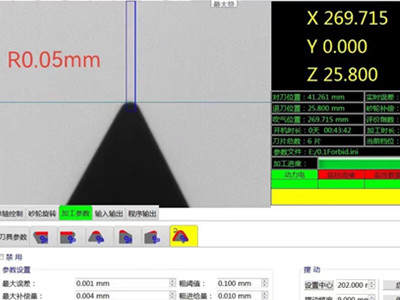

- Fast feeding and withdrawing, constant pressure grinding, on-line inspection

- Tip radius: R0.1 - R6 mm

M50 tools grinding machine has characteristics of tight configuration , quick action and high sensitivity. The functions of the machine including fast feeding and withdrawing, constant pressure grinding, on-line inspection, wheel spindle oscillation controlling by servo motor, etc.

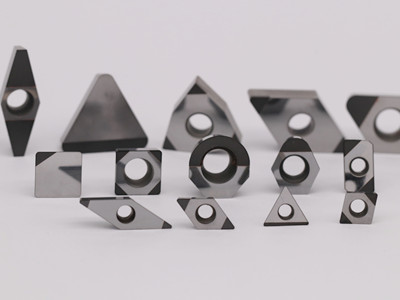

The M50 manual PCD machine is suitable for grinding or regrinding PCD, CBN, MCD, CVD tools, clip blade, non- standard turning tool, boring tool, ceramics, carbide and HSS tools, also can be used as tool grinding.

Technical Parameters - M50 Manual PCD Tool Grinder

|

Grinding spindle inclination: -5°- 25°

Tip radius: R0.1 - R5MM

Grinding spindle speed: 1000-4200 rpm

Spindle oscillation frequency: <= 40 strokes/min

Grinding spindle oscillation size: 0- 40mm

Grinding spindle motor power: 2.2kw

Vitrified diamond wheel size: 150x40x40

Total power: 3.5kw

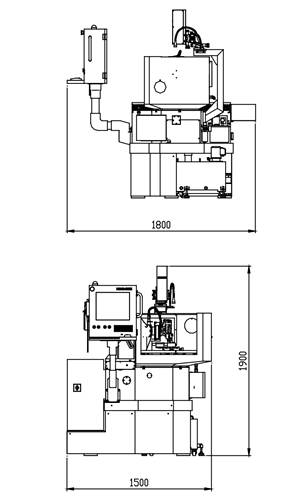

Dimension: 1500x1720x1850mm

Net weight: about 1200kg |

Object distance of lens: 300mm

Monitor size: 19”

Monitor resolution: 1600x900

Slider feeding size: 70mm

Worktable swiveling angle: 0-240°

Worktable travel: 60x60mm

Contact pressure: 0-400N

Optical scale resolution: 0.001mm

Encoder resolution: 0.036°

|

The Standard Configuration

- The main part of machine

- Power supply and control system

- Work station

- Imaging system

- Pneumatic unit

- Work light and backlight

- Coolant tank

- Grinding wheel dresser

- Adjustable quick mounting fixture

- Standard accessories

- Technical documentation

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088