Drilling in deep, abrasive, and extremely hard rock formations—such as quartz sandstone, flint, granite, hard limestone, and basalt—poses significant challenges. Traditional PDC cutters tend to suffer from rapid wear, impact breakage, thermal degradation, and poor penetration in these harsh conditions.

To maintain drilling efficiency and extend bit life, it is essential to choose PDC cutters specially engineered with high wear resistance, superior impact toughness, and outstanding thermal stability. This article provides a detailed guide for selecting the right PDC cutters for deep and hard rock drilling.

1. Increased Diamond Layer

Thickness: Extending Cutter Life Standard PDC cutters typically feature a 1.5–2.0 mm diamond layer, which wears out quickly in abrasive formations.

Recommended: 2.5–4.0 mm thick diamond layer

Advantages:

Longer wear life

Better edge retention

Improved ROP in abrasive formations

Suitable for long intervals and continuous hard-rock drilling

A thicker diamond table significantly enhances durability under high abrasive loads.

2. Superior Thermal Stability: Preventing Graphitization

Downhole temperatures in deep hard formations may reach 200–300°C, while the cutter–rock interface can exceed 700–800°C.Conventional PDC cutters graphitize above 750°C, causing rapid wear and structural failure due to cobalt depletion. Recommended: Thermally Stable or De-cobaltized PDC Cutters (TSP-enhanced)These cutters withstand temperatures up to 1200°C or higher.

Advantages:

Resistance to graphitization

Stable mechanical strength at high temperatures

Ideal for quartz-rich, high-abrasion, and volcanic rock formations

3.High Impact Toughness: Improving Cutter Integrity

Hard formations generate strong vibrations and irregular impacts, making traditional PDC cutters prone to: chipping micro-cracking catastrophic breakage

Recommended: PDC cutters with a wavy or engineered interface

Benefits: Stronger bond strength between diamond and carbide substrate

Better energy dispersion

Reduced risk of delamination and cracking

Enhanced stability under high WOB and torque

This design dramatically improves cutter survival in deep and fractured formations.

4.Optimal PDC Cutter Geometry and Back Rake

Angle Hard-rock drilling requires not only wear resistance but also efficient penetration.

Recommended cutter shapes: Conical or Dome-shaped PDC

Sharper cutting edges

Better penetration with lower WOB

Reduced vibration and torque fluctuations

Improved performance in granite, flint, and other ultra-hard rocks

Recommended back rake angle: 15°–25°

A proper back rake ensures: Adequate edge support Controlled penetration Lower risk of cutter sticking, over-engagement, or breakage

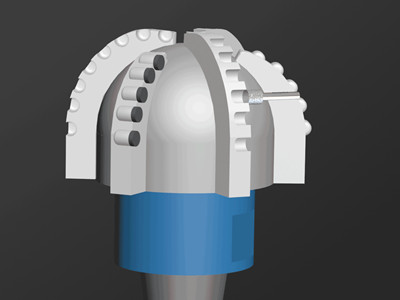

5.Cutter Layout & Bit Body Selection: Maximizing Bit Performance

Even the best PDC cutter cannot perform without a proper bit design.

High cutter density is essential in hard rock

Benefits:

Lower load on each cutter

Reduced wear rate

Improved bit stability and drilling efficiency

Preferred bit body: Matrix-body PDC bit

Compared with steel-body bits, matrix-body bits offer

Higher wear resistance

Superior performance in high-abrasion formations

Longer life under high impact and high-temperature conditions

Matrix-body PDC bits are commonly used in: Granite Quartz sandstone Basalt Highly abrasive composite formations

Key Requirements for PDC Cutters in Deep Hard-Rock Drilling

To achieve reliable and efficient drilling in deep, abrasive, and ultra-hard formations, PDC cutters should have:

✔ Thicker diamond table (2.5–4.0 mm)

✔ High thermal stability (up to 1200°C+)

✔ Enhanced impact toughness (wavy interface design)

✔ Conical or dome-shaped geometry with 15°–25° back rake

✔ High cutter density

✔ Matrix-body PDC bit structure

This combination ensures improved penetration rate, longer bit life, and reduced drilling costs in demanding geological environments.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088