Recently, we received an inquiry regarding the selection of grinding wheels for PDC composite inserts. Based on the three product drawings and on-site processing conditions provided by the customer, we first analyzed the core processing needs and the root causes of the problems. Based on this analysis, we systematically reviewed the selection logic and industry-specific solutions for PDC composite insert grinding wheels, aiming to provide a reference technical approach for similar processing scenarios.

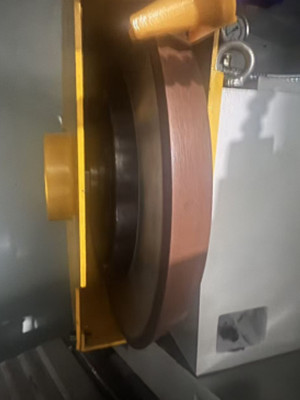

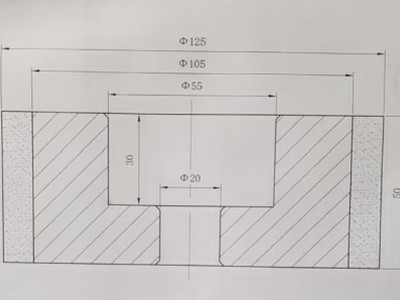

The customer currently uses a standard cylindrical grinding machine, primarily for processing PDC cutter used in the petroleum industry. They are currently using a resin-bonded diamond grinding wheel, but report problems with excessive wheel wear and ineffective grinding. Based on the drawing requirements (machining allowance of 15-20 microns, surface roughness Ra 0.8 or less) and on-site process, the core problems are initially identified as follows:

- Mismatched grinding wheel hardness: The existing grinding wheel is too soft and cannot withstand the high hardness requirements of PDC composite insert processing, leading to excessive wear;

- Insufficient grinding wheel concentration: Normal processing of PDC composite inserts requires a resin-bonded grinding wheel with a concentration of 125% or higher. The current grinding wheel concentration may not meet this standard, affecting grinding efficiency;

Currently, the grinding wheels suitable for PDC composite insert grinding are mainly ceramic-bonded diamond grinding wheels and resin-bonded diamond grinding wheels. These two types have significant differences in characteristics and cover different market segments. The specific comparison is as follows:

- Ceramic-bonded diamond grinding wheels: Possess the core advantages of long service life and high processing accuracy, reliably ensuring precision machining requirements, and dominating the high-end PDC composite insert processing market.

- Resin-bonded diamond grinding wheels: Offer cost advantages and high surface finish characteristics, with strong processing compatibility, making them more suitable for mid-to-low-end precision machining scenarios and a preferred choice for cost-effective needs.

The core application scenarios for PDC composite inserts are concentrated in oil and gas drilling, mining, and geological exploration. The working conditions in these different scenarios vary significantly, requiring precisely matched grinding wheel selection solutions, as follows:

1. Oil and Gas Drilling

Demand characteristics: Primarily used in the manufacturing and repair of PDC drill bits, requiring extremely high wear resistance and impact resistance from the grinding wheels to ensure stability and consistency in mass production.

Recommended grinding wheels: For external cylindrical grinding, 1A1 ceramic diamond grinding wheels are preferred; resin centerless grinding wheels can be used for finishing processes.

Industry data: By 2025, the oil drilling sector will account for 58% of the total demand for PDC composite inserts, making it currently the largest application market.

2. Mining and Geological Exploration

Demand characteristics: Focused on the grinding of hard rock drill bits, requiring adaptation to high-hardness, high-load processing needs under complex geological conditions.

Recommended grinding wheels: High-concentration ceramic diamond grinding wheels, with a grit size range of 60#-120# (adjustable according to the specific machining allowance; 60#-80# for rough grinding, 100#-120# for semi-finishing).

Industry trends: The mining tools sector is the fastest-growing segment for PDC composite insert demand, with a growth rate of 14.7%, becoming a core driving force for future industry growth.

Based on three core dimensions—processing requirements, precision standards, and cost budget—the general selection principles for PDC cutter grinding wheels can be summarized as follows:

1. High-volume precision machining scenarios: Ceramic-bonded diamond grinding wheels are preferred to maximize the stability of processing accuracy and grinding wheel lifespan, reducing long-term processing costs.

2. Medium-to-low cost precision machining scenarios: Resin-bonded diamond grinding wheels are a cost-effective choice, requiring careful control of grinding wheel concentration (not less than 125%) and hardness selection, while also matching appropriate dressing processes.

3. Complex shape machining scenarios: For PDC cutter with special geometric shapes, metal-bonded diamond grinding wheels can be used due to their good formability, allowing them to adapt to irregular machining requirements.

Based on the customer's requirements for this inquiry, it is recommended to prioritize optimizing the concentration (increasing it to over 125%) and hardness grade of the existing resin-bonded grinding wheels. For rough grinding, use grit sizes of 120# to 140#. If higher processing efficiency and longer lifespan are desired, consider upgrading to ceramic-bonded diamond grinding wheels and adding roller dressing equipment to accommodate the processing requirements of angled products.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088