Diamond crystals belong to the cubic crystal system. Due to the difference in atomic arrangement and atomic density on each crystal plane and the distance between crystal planes, the anisotropy of natural diamond crystals is caused. Therefore, diamond not only has different physical and mechanical properties of each crystal plane, but also has different manufacturing difficulty and service life, and the microscopic damage strength of each crystal plane is also significantly different.

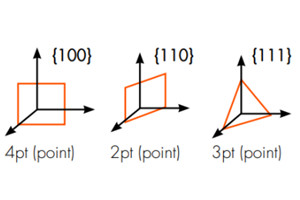

The three primary crystal orientation are {111}, {100} and {110} in diamond industry, which described as 3 point, 4 point and 2 point respectively.

Customer case: Size: 1x1x4mm MCD, 0.5x0.5x4mm CVD

Application: Diamond tool

.jpg)

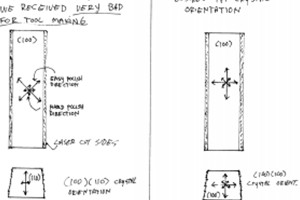

Customer desired 4pt diamond

Generally, if the diamond tool is required to obtain the highest strength, the (100) suitable as tool orthogonal rake and tool clearance; if required to resist mechanical wear, the (110) suitable as tool orthogonal rake and tool clearance; if required to resist chemical wear, the (110) suitable as tool orthogonal rake, the (100) as the clearance, or the (100) for both the front and flank.

Moresuperhard provide different crytsal orientations of CVD and MCD diamond plate for diamond cutting tools.If you need,please contact us freely.Whatsmore,hope our article is useful for you.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088