Study on the Grinding Quality of PCD Tool Diamond Grinding Wheel

The importance of high quality PCD cuuting edge

PCD tools must ensure a good cutting edge before processing the workpiece, and diamond grinding wheel grinding is currently the most widely used method. Studies have shown that the higher the cutting edge quality, the finer the tool marks left at the junction of the tool geometric reflection area on the workpiece processing surface, and the higher the surface finish of the processed workpiece. Because the chipping or expansion of the cutting edge can easily cause tool wear or damage, reducing the service life of the tool. Edge chipping is a key indicator of diamond tool edge quality.

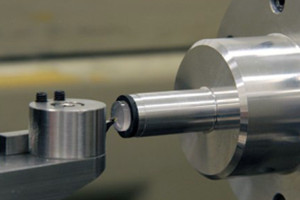

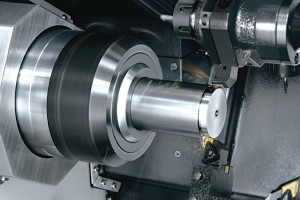

Grinding Mechanism of PCD Tool

The abrasive grains of the diamond grinding wheel continuously impact the PCD material, causing the diamond on the PCD to undergo brittle fracture (including intragranular microfracture, intergranular fracture and cleavage fracture), sliding wear, and scratching; thermochemical action is the grinding process. The resulting high temperature oxidizes or graphitizes the diamond. There are many factors that affect the cutting edge quality of PCD tools, such as the particle size of diamond micropowder in PCD composite sheet, the type of diamond grinding wheel, equipment performance and the rigidity of fixtures, etc.

1.Diamond micropowder particle size in PCD composite sheet

Under other conditions being the same, there is a positive correlation between the particle size of the diamond powder of the PCD material and the chipping of the tool edge, that is, the larger the particle size of the diamond powder, the larger the chipping of the cutting edge. At the same time, the edge chipping of the mixed particle size is smaller than that of the coarse particle, and closer to the medium particle size. This is because the pure coarse particle is filled with a metal binder in the middle, while the mixed particle size is that there is metal bond and other fine-grained between the coarse particles.

During the sharpening process, the diamond abrasive grains of the grinding wheel continuously impact the edge of the PCD tool. The plasticity of the PCD tool is poor, and microscopic chipping will occur at the edge.From the microscopic analysis, the diamond particles in the PCD tool are brittle and broken when being squeezed and rubbed, and form a chip.The size of the chip formed by brittle crushing is positively correlated with the particle size of the diamond powder. The larger the particle size, the larger the chip.In addition, because the hardness of the diamond abrasive of the fine grinding wheel is lower than that of the diamond particles in the medium and coarse grained PCD, the scoring effect of the abrasive is weak, but the abrasive of the fine grinding wheel is easy to wear and block, and when the grinding temperature is high, friction and thermochemical effects Dominant, which reduces or eliminates the larger chipping that occurs in brittle fracture, so the final edge chipping is smaller than the coarse-grained size.

2.Types of diamond grinding wheels

Chipping sequence:metal bond diamond grinding wheel>vitrified bond diamond grinding wheel >resin bond diamond grinding wheel.When the grinding wheel particle size is larger than W10, the edge chipping value is very sensitive to the grinding wheel particle size, and increases with the particle size; when the grinding wheel particle size is smaller than W10, the cutting edge chipping value is not sensitive to the grinding wheel particle size.In the sharpening process of PCD tools, higher or lower speeds cannot guarantee the quality of the edge, and a moderate speed is required to obtain the smallest edge chipping. The rigidity and precision of the sharpening machine affect the range of the optimal speed interval

3.Equipment speed

In the sharpening process of PCD tools, higher or lower speeds cannot guarantee the quality of the edge, and a moderate speed is required to obtain the smallest edge chipping. The rigidity and precision of the sharpening machine affect the range of the optimal speed interval.

4.Grinding pressure

In general, the maximum value of edge chipping increases with the increase of grinding pressure.As the grinding pressure increases, the extrusion effect of individual abrasive grains on PCD will also increase, making PCD more prone to cleavage fracture and fatigue fracture.If the pressure is too small, the grinding efficiency will be low, and if the pressure is too high, the cutting edge will be prone to chipping. It is necessary to determine the appropriate grinding pressure according to the equipment conditions.

To sum up, the key to the quality of PCD tool edge grinding with diamond grinding wheel is not to produce edge chipping. It is necessary to determine the appropriate processing technology according to different PCD grades to ensure a good processing edge and prolong the life of PCD tools. Longer service life and improved surface quality of machined workpieces

<< :ultra-hard abrasives grinding wheel dressing solutions-diamond roller dressing method

<< :How to choose the appropriate crystal plane when sharpening diamond tools

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088