Experience is the best teacher. MORESUPERHARD was born with many years of experience in tool grinding, and its original intention was to help customers solve the problem of super-hard tool grinding.

our journey

2014:MORESUPERHARD founded.

2015: established PCD division for solving super-hard cutting tools processing problems and established R&D center at the same time.

2017: established grinding data collection and analysis center .The R&D center of MCD tool grinding was officially invested.

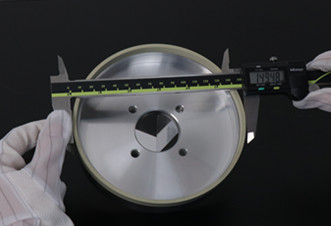

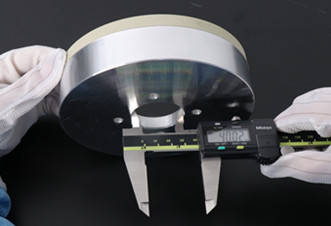

2020:moresuperhard sucessfully producted 1mm ultra-narrow ring width vitrified diamond grinding wheel.

2021:moresuperhard sucessfully produced 1μm ultra-fine-grained vitrified diamond grinding wheel.

2022:to be continued.

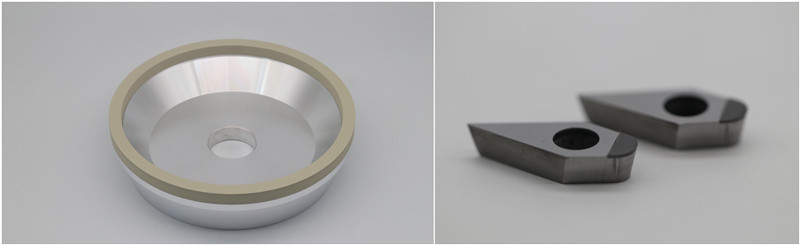

moresuperhard independent research and develop "533" and "053" series vitrified diamond grinding wheel to meet the needs of customers for ultra-small size PCD, PCBN tools grinding.

"533" is ultra-precision grinding wheel with particle size of 3μm, "053" is ultra-precision grinding wheel with particle size of 1μm

moresuperhard first developed fine-grained grinding wheels for high precise PCD tools process

Because traditional tools cannot meet the high efficiency and high precision requirements of high-precision industries, PCD materials enter various industries as the world's hardest tool materials. However, while the work efficiency is improved, a problem is also exposed - the machining accuracy of PCD tools cannot meet the requirements. After many measurements and studies, it was found that the occurrence of this situation was caused by the excessive collapse of the tool material itself, and the main reason for this problem was that the quality of domestic fine-grained grinding wheels was not as good as foreign ones. In order to meet the needs of more high-end customers, Moao began to focus on the research and development of fine-grained grinding wheels. At present, it has successfully solved the problems of difficult PCD material processing, low efficiency, short life and unsatisfactory precision for customers.

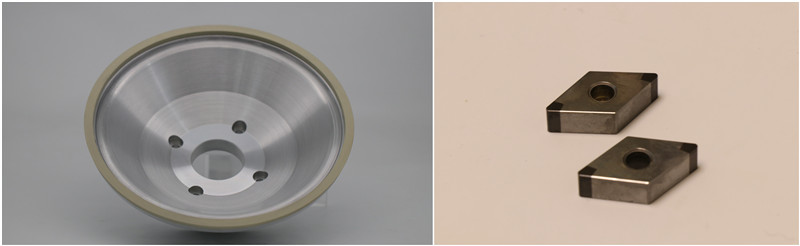

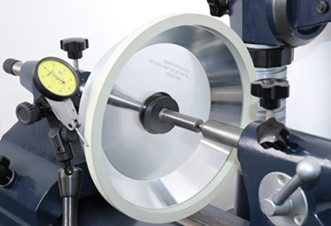

moresuperhard further increased the CBN tool grinding production line

In the process of solving different problems for customers, we found that affected by the material properties, CBN tools have more advantages than PCD tools in the processing of some iron arrowhead metals. moresuperhard further increased the CBN tool grinding production line. Up to now, we have developed two different bond diamond grinding wheels, ceramic and resin, which can meet the processing needs of multiple CBN tools according to the grinding processing conditions of different customers.

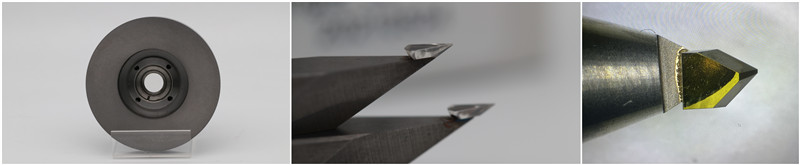

moresuperhard now specializes in the grinding wheels for processing single crystal tools

In recent years, with the rapid development of infrared, medical, and optical industries, single crystal tools have rapidly entered aerospace, mechanical weapon manufacturing and other industries. Even watches and jewelry that can be seen everywhere have begun to use single crystal tools for processing. According to customer processing equipment, industry precision requirements, and manufacturing capabilities, moresuperhard now specializes in the development of ceramic/metal bond grinding wheels, which are respectively applied to rough and fine grinding of single crystal tools, and have received many good feedbacks.

Our production and services covered

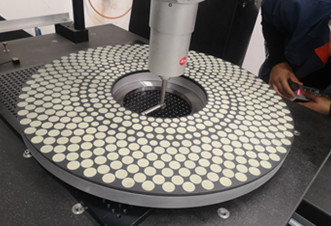

The "Ceramic Grinding Everything" project was launched. Since entering 2020, Moao has specially established a "Ceramic Grinding Everything" project team according to the market situation, which is specially used to integrate the needs of customers for grinding various materials, including cemented carbide, ceramics, cermets, etc.

In order to help customers to make a further decreasing in the production cost, and also to protect the environment and recycle the non-renewable resources

Vitrified bond diamond grinding wheels possess pretty high abrasive resistance, especially in polishing hard and brittle workpiece. It has many advantages like high grinding efficiency, high grinding precision, excellent workpiece's surface grinding, etc

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088