- PCD(Polycrystalline diamond) /PCBN/ CVD cutting tools can outperform by carbide by a ratio 30-50times as well as it can get a better surface finishing than carbide. The best quality of sharpened edge of the PCD tools can achieve the excellent tool life which is certainly reduces the unit cost in present white-hot cutting tools market. MoreSuperhard provides private custom PCD PCBN MCD Carbide and Ceramic cutting tools grinding and regrind solutions and services at first class. Surely, the effective diamond grinding wheels and grinding machines are our powerful core products which can match the EWAG, Coborn, MYTECH, Farman and any other grinding machine perfectly because we can make different series grinding wheel for PCD with different grain sizes, area sizes, lengths, thicknesses, shapes, combined conditions with carbide substrate, as well as PCBN,CBN, CVD, MCD, ND, these superhard precision tools.

CMP (Chemical Mechanical Polishing) technology for CVD diamond enables ultra-smooth surfaces with nanometer-level roughness. By combining mechanical abrasion with chemical reactions, CMP delivers superior flatness, high precision, and damage-free polishing.

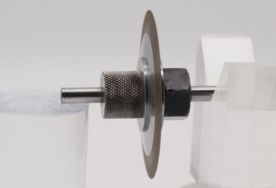

Learn how a customer optimized the grinding process for PCD scissors using vitrified and resin bond grinding wheels. This case highlights efficiency improvements and multi-material grinding solutions for textile machinery parts. Discover practical solutions to enhance grinding speeds and results with advanced wheel choices.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088