Diamond has the advantages of extremely high hardness and wear resistance, low friction coefficient, high elastic modulus, high thermal conductivity, low thermal expansion coefficient, and low affinity with non-ferrous metals. It is currently the hardest tool material. It is mainly divided into single There are two categories: crystalline diamond and polycrystalline diamond. Single crystal diamond is divided into natural single crystal diamond (abbreviation: ND) and artificial single crystal diamond. Artificial single crystal diamond is divided into CVD single crystal diamond and HPHT(high pressure and high temperature) diamond. Polycrystalline diamond is divided into polycrystalline diamond (PCD) and chemical vapor deposition (CVD). There are many types of diamond tools with significant differences in performance. The structures, preparation methods and application fields of different types of diamond tools are quite different.

Procession of producing CVD diamond cutting tools

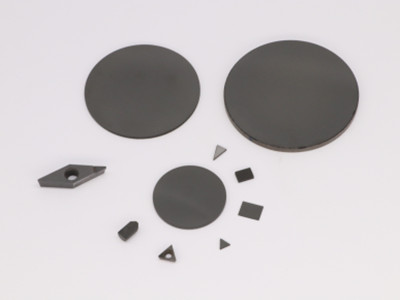

Polycrystalline diamond (PCD)

HPHT diamond plate

CVD single crystal diamond plate

General speaking,Polycrystalline diamond can be laser cut and EDM cut due to its conductivity properties.But CVD diamond and HPHT diamond only can be laser cut due to non-conductivity.Moresuperhard provide precision laser cutting machine for cutting PCD diamond,CVD diamond plate and MCD diamond plate.The advantages of laser cutting diamond are high precision, no contact, wide applicability, small thermal impact and high degree of automation.The problem is that the price of a diamond laser cutting machine is 3 to 4 times the price of a WEDM cutting machine.

In order to help customers reduce the cutting costs of CVD diamond sheets, MORESUPERHARD has been developing conductive CVD diamond for cutting tools.CVD diamond can be doped with boron to make it electrically conductive and can be cut using EDM machines.

EDM wire cutting Laser cutting PCD diamond

Welding methods mainly include laser welding, vacuum diffusion welding, vacuum brazing, high-frequency induction brazing, etc. At present, high-frequency induction heating brazing PCD blade welding is widely used with low investment and low cost.

The interfacial energy between CVD single crystal diamond and general metals and their alloys is very high, so that the diamond cannot be wetted by general low melting point alloys, and its weldability is extremely poor. At present, the welding process of CVD diamond tools mainly adopts the active metallization method. The solder is a silver-copper alloy containing iron, without adding flux, and is welded in an inert protective gas or vacuum. It uses high-frequency induction heating with a heating temperature of 850°C.As a full grinding solutions supplier,Moresuperhard provide high frequency brazing machine for your PCD cutting tools and vacuum brazing machine for your CVD diamond cutting tools.

High frequency brazing vacuum brazing

In view of the performance characteristics of single crystal diamond tools and the quality requirements after processing, the Moresuperhard R&D department strictly screened and controlled the diamond crystal form and grade, improved the formula, adjusted the production process, conducted multiple grinding experiments, and developed a high-performance Rough grinding, semi-fine grinding, fine grinding, and super-fine grinding ceramic bonded and metal bonded diamond grinding wheels that stabilize and ensure grinding edge quality. Professionally solve the grinding problems of single crystal knife with high grinding efficiency, good retention, no edge chipping, stable sharpening quality, ensuring the arc accuracy of the tool tip and long-lasting and more durable.

CVD (Chemical Vapor Deposition) cutting tools have huge development prospects, mainly based on their excellent performance, wide range of application fields, efficient processing technology, multi-functional design, sustainable development and continuously innovative technology. As a high-performance and efficient tool manufacturing technology, CVD tools will play an increasingly important role in modern manufacturing, providing more efficient and reliable processing solutions for various processing fields and promoting the development of the manufacturing industry.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088