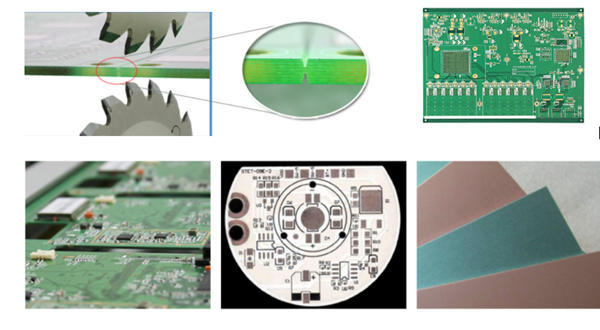

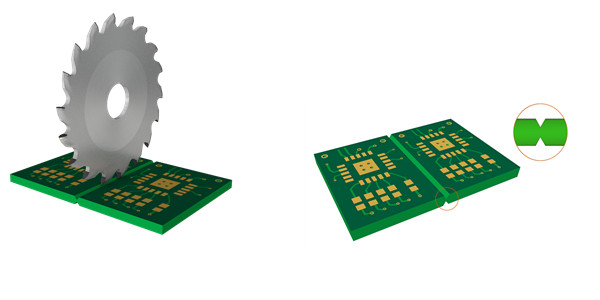

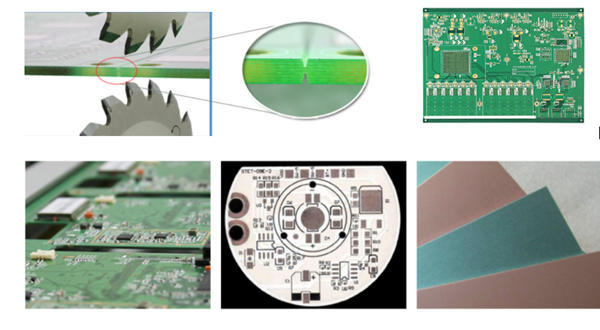

With the development of the PCB electronics industry, the market demand for V-CUT cutter for circuit board cutting is increasing. V-CUT cutter have become a cutting tool for modern industrial production and processing due to their excellent performance. The v-cut blade has strong teeth, sharp side edges, and the processed PCB (circuit board) has a high surface finish, no burrs, and a long service life.

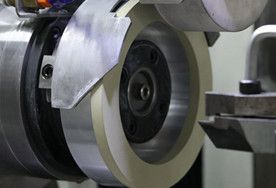

What grinding wheel is used to grind the V-cut cutter ?

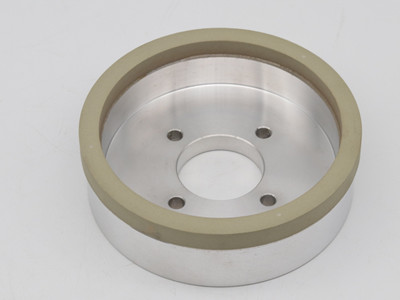

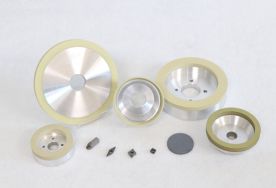

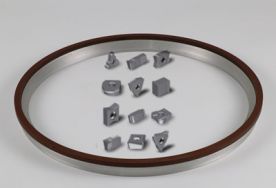

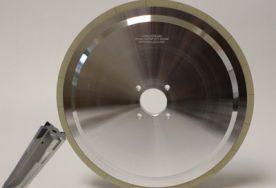

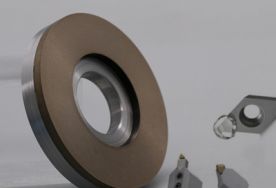

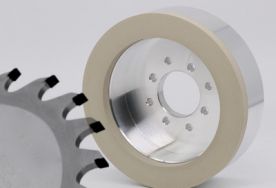

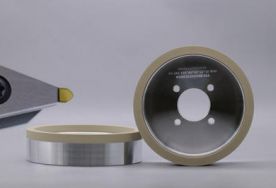

Moresuperhard can provide high-quality vitrified (ceramic) diamond grinding wheels for rough and fine grinding of PCB circuit boards, V-Cut cutter, woodworking saw blades and other pcd tools.

Vitrified (Ceramic) diamond grinding wheel has better mechanical strength, long service life, fast cutting speed, good heat resistance, sharp cutting, high grinding efficiency, and it is not easy to accumulate heat during the grinding process, and it is not easy to cause blockage. It perfectly solves the problem of low efficiency, poor cutting edge quality, and chip stacking in the process of processing circuit boards, resulting in burrs in the finished product, reducing costs for customers. In the case of normal wear and tear, the V-CUT tool must be ground by 0.25mm to 0.35mm each time, that is, the diameter is reduced by 0.5mm to 0.7mm. When a new tool is worn and the gap is not greater than 0.35mm, the number of times of grinding is about 5 times.

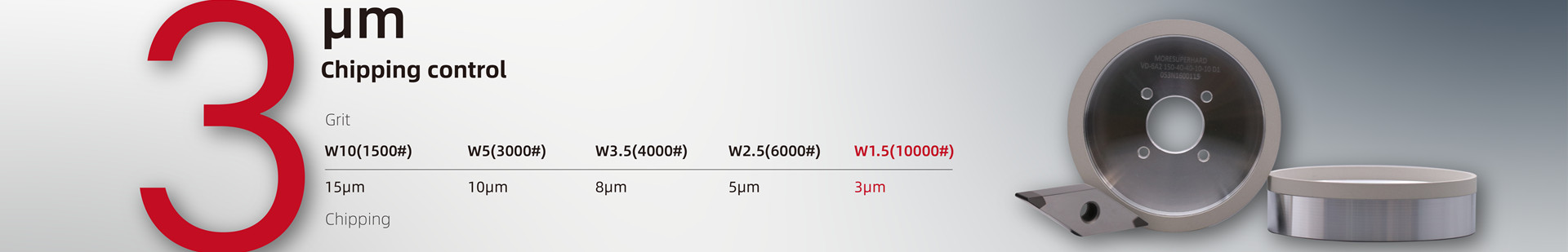

Grinding parameters of vitrified diamond grinding wheel

Speed: 2000-2500r/min

Feed per time: 0.001-0.002mm

Vitrifirf diamond grinding wheel shape: cup, flat, bowl, dish

Granularity: W40, W28, W20

Specifications: Special sizes can be customized according to customer needs

Features of Vitrified (Ceramic) Diamond Grinding Wheel

- The porous structure makes the passivated diamond easier to fall off, reduces the grinding resistance, prevents the vertical streaks on the workpiece and improves the surface finish quality

- Perfect dimensional tolerance control, suitable for CNC and manual tool grinders

- Good self-sharpening, high grinding efficiency, high wear resistance and low consumption of abrasive particles

- The use of vitrified bond can make PCD PCBN tools achieve good surface finish and avoid edge chipping, thereby reducing scrap rate and improving the grinding accuracy of PCD/CBN tools

- The service life of vitrified bond grinding wheel is several times longer than that of resin bond grinding wheel and can be easily dressed in-line

Application areas of diamond PCD V-CUT tools

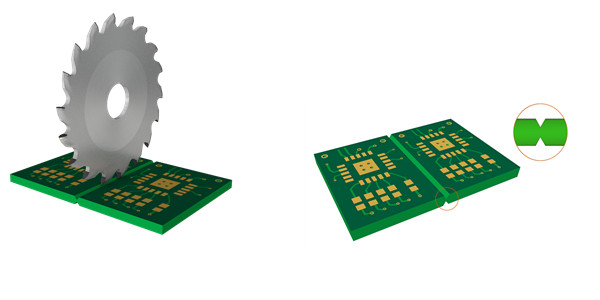

1. V-cutter can be used for cutting double-sided copper clad PCB circuit boards, various glass fiber FR2 boards, glass fiber FR4 boards, copper clad laminates, aluminum substrates, copper substrates, high TG boards, halogen-free boards, iron substrates, CEM1, CEM3 material circuits plate.

2. V-cutter is also suitable for V-groove processing of PCB circuit boards in other industries.

Why choose diamond PCD V-Cut tool to process PCB circuit board?

- The hardness of polycrystalline is as high as 8000HV, and diamond is one of the hardest substances on earth. The product has good wear resistance, and the wear resistance can reach 50 times that of cemented carbide. - Long service life: Take the FR-4 board as an example, the normal operation is that the groove is cut 30,000-40,000 meters at a time, and when the use condition is good, the service life can reach 50,000-60,000 meters.

- PCB diamond V-CUT cutter for PCB circuit board V-slot

- The tool distance can be automatically adjusted according to the thickness of the circuit board to reduce tool wear.

- The V-grooving operation has high precision, one-time forming, and longer service life.

- Ideal for machining aluminium substrates, suitable for dry cutting operations.

- The relative wear resistance improves the stability of the line width.